Care for Your Product

When it is necessary to treat the board with mineral oil?

Time for treatment of a board depends on many factors, but the main thing is moisture variations in the room. A board can stay untreated for months under small variations of moisture and nothing will happen. However, in wintertime heating season starts and air moisture greatly decrease. At this time, it is necessary to treat board with oil more often. There is no strict rule how often you should do it. Nevertheless, we can give you few advices.

- A board becomes noticeably brighter;

- Light spots starts to appear in some places of a board;

- To the touch board becomes “dry” and rough

- On the side face of a board microcracks appeared, which are invisible, but you can feel them with fingers;

- Water or liquid products does not stay on the surface of the board (as it should be), but it is absorbed inside the board.

All the signs are that it is time to good treatment of cutting board with mineral oil.

Treatment

Treatment is easy and only requires you to buff on board wax or a substitute product and to apply oil back into the complete surface of the wood, both sides and ends. Give time for the wood to suck in the product and then buff out the remainder.

Some Species will require more product than others depending on many factors including porosity and the end sanding grit.

Hygiene of wood cutting boards

There is a belief fed by producers that in comparing with non-wood cutting boards the wood ones creates a positive environment for generation of bacteria and germs. But for a hundred or maybe thousand years people use wooden utensils in cookery and the reason of it not only cheapness and availability of wood.

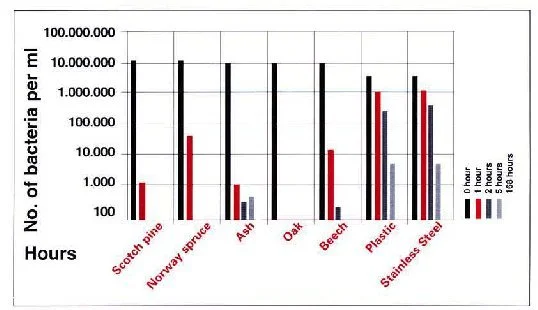

Recent studies led in Danish Technological Institute show and leading German, Sweden and Finland research institutes affirm absolutely contrary information - anti-bacterial properties of the wooden utensils are better than of utensils made of other materials.

In the laboratory examinations we have inoculated harmless bacteria into different wood species (oad, pine, Norway spruce, beech and ash), plasitc and steel. These bacteria are in many ways similar to the feared bacteria Salmonella, Camphylobacter and Listeria. Then the survival time for bacteria was measured.

There are some study findings:

Bacteria have essentially poorer life conditions on wood compared with synthetic materials and steel;

Bacteria have poor life conditions on wood, especially dry wood.

Source: http://www.kitchensource.com/cutting-boards/pdf/chopblockhygiene.pdf

Similar study was conducted in the University of Wisconsin-Madison called “Wood cutting boards, not plastic, are safer for food preparation”.

For decades now, cooks in homes and restaurants have been urged to use plastic rather than wood cutting boards in the name of food safety. The fear is that disease-causing bacteria, e.g. salmonella, from raw chicken will soak into a cutting board and later contaminate other foods cut on the same surface and served uncooked, such as salad ingredients etc.

Dean O. Cliver and Nese O. Ak, food microbiologists in the College of Agricultural and Life Sciences, have found that in some as yet unknown way wooden cutting boards kill bacteria that survive well on plastic boards. “Our original objectives were to learn about bacterial contamination of wood cutting boards and to find a way to decontaminate the wood so it would be almost as safe as plastic. That's not what happened!” says Cliver.

Source:http://www.kitchensource.com/kitchen-islands/pdf/woodvsplastic.pdf